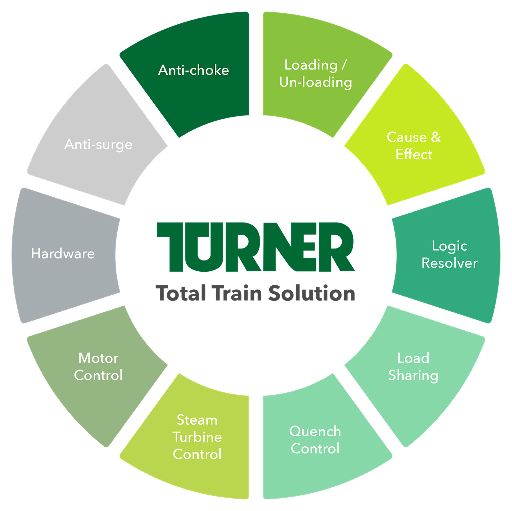

Turner ECS Integrated Turbine & Compressor Control (ITCC) solution maximize availability and performance in upstream, midstream and downstream oil and gas applications, helping owners run their compression systems and process at peak efficiencies. The new API670 standards require a total systems approach to meet the safety levels required in the industry.

Woodward is a leader in delivering steam turbine and compressor safety systems to meet these new standards. From compressor surge detection, to lube oil, seal gas and suction scrubber level protection, our safety systems are powerful, reliable, easy to use, and flexible for your operating environment.

Major benefits of our Integrated Turbine Compressor Control:

-

One Integrated Control System

-

Reduction in wiring and system

-

Simple to operate

-

Simple to support

-

Cost savings in spares

-

Faster interaction between the motor/turbine and the compressor resulting in a more stable process.

-

Easy for operators to understand and manage system.

-

Lower risks of operation problems.

-

Protects motor from overload conditions.

Compressor safety

The new API670 standards require a total systems approach to meet the safety levels required in the industry. Woodward is a leader in delivering steam turbine and compressor safety systems to meet these new standards. From compressor surge detection, to lube oil, seal gas and suction scrubber level protection, our safety systems are powerful, reliable, easy to use, and flexible for your operating environment.

Advanced technology

Woodward has developed surge preventive techniques that help compressor users achieve peak performance of their process and minimize process disturbances. All our solutions are modeled in our advanced dynamic simulation program (NetSim) before being implemented in the control systems. Woodward’s patented rate PID algorithms provide anticipative opening of anti-surge valves during process upsets to minimize overshoots and allow safe operations with minimal safety margins. Compressor turndown is maximized and higher product yields are achieved.

Dynamic Simulation

Woodward’s proven NetSim™ simulation packages provide integrated turbomachinery-specific dynamic modules of the compressor, prime mover and auxiliaries, along with real-time control models that can run on a single computer. This benefits the users in running FEED/ Feasibility/RCA Studies and aids in control system design and testing. NetSim™ emulates functionality of all system hardware components, accurately reproducing execution timing, I/O synchronization and data protocols.